The Chevy Equinox EV stands out as a crucial addition to General Motors’ lineup. Ahead of the anticipated rebirth of the Bolt EUV next year, this crossover will be the most affordable electric vehicle offered by the automaker and one of the most economical lithium-ion-powered EVs currently available. The Equinox EV’s battery is notable for showcasing both the advantages and limitations of GM’s Ultium platform, particularly regarding the modules it now produces.

In summary, it offers an impressive range and price combination. However, a significant consideration is voltage, and I’m about to explore what this means for potential buyers.

| Vehicle | |

| Battery Chemistry | NMC (3.6V – 3.7V nominal) |

| Cell Form Factor | Pouch |

| Cell Capacity | 103Ah (~371Wh) |

| Total Module Count | 10 |

| Module Configuration | 8S 3P |

| Pack Configuration | 80S 3P |

| Nominal Pack Voltage (3.6V) | 288V |

| Calculated Pack Capacity (total at nominal voltage) | 89.0 kWh |

| Reported Usable Capacity | 85 kWh |

The battery module utilized in the Equinox EV is identical to those employed in all Ultium-based EVs manufactured thus far. With a nominal voltage of approximately 28.8V, this characteristic holds significant importance. Even in larger pack Ultium vehicles like the 12-module Cadillac Lyriq, each cluster of cells is interconnected in series, indicating that the pack voltage at the terminals is entirely contingent on the quantity of modules installed.

This implies that the Equinox EV’s 85 kWh pack had to undergo a voltage reduction to attain the lower capacity required to lower the vehicle’s price. With only 10 modules installed in the vehicle’s floor, resulting in an 80S pack configuration, the nominal voltage stands at 288V. Consequently, the Equinox does not truly feature a 400V architecture; instead, it operates more like a 300V system. (Interestingly, the Corvette E-Ray’s hybrid battery also boasts a nominal voltage of 288V, although much of its true capacity remains unused).

But what are the implications of this in the broader context? Well, it means that the Equinox EV cannot charge as rapidly as larger counterparts like the Blazer EV with its 102 kWh battery or the Lyriq. The Equinox EV’s maximum charging rate caps at 150kW, whereas those vehicles can achieve 190kW. Typically, higher voltages correlate with faster charge speeds, and a reduction in voltage results in a slower charge unless the amperage, which is the other component of power alongside voltage, is elevated to compensate. Unfortunately, this isn’t feasible in this scenario.

Charging efficiency hinges on voltage and current, with wattage being the product of the two. A car capable of charging at 50kW—equivalent to 50,000 watts—achieves this through a specific combination of voltage and current.

Now, onto the technical aspect, which may seem daunting, but it will soon become clear.

Individual battery cells exhibit charged, nominal, and discharged voltages. For lithium-ion Nickel Manganese Cobalt (NMC) cells, these values typically range around 4.2V when charged, 3.6V nominally, and 2.8V when discharged. While these limits can be slightly exceeded or reduced, doing so usually shortens the cell’s lifespan. Some automakers push their battery cells to as high as 4.25V during charging to attain a slightly extended range, but this practice may impact longevity. Notably, GM does not adopt this approach, as seen in the new electric Dodge Charger (if its specifications are accurate).

Charging a battery cell involves applying its charged voltage across the terminals at a specific current level. To expedite charging, more current can be applied, while voltage remains constant. However, cells have defined ratings indicating the maximum current they can withstand and for how long. Exceeding these limits can lead to various issues, including reduced cycle life, accelerated passive discharge, and, in extreme cases, expansion, smoking, or even fire—though the latter is rare without severe abuse.

The battery pack’s voltage is determined by the internal wiring of the cells. In the case of the Equinox, it consists of three parallel groups of 80 cells in series, resulting in a nominal pack voltage of 288V (3.6V multiplied by 80). While theoretically, higher current could facilitate faster charging, it’s constrained by the aforementioned cell ratings. Increased current generates more heat, which must be dissipated, potentially exceeding the capacity of the cells or the pack’s cooling system.

GM understands the Equinox EV’s charging voltage and the cells’ current capacity during continuous charging. For instance, if the pack were charged at 336V, applying five amps would yield a charging rate of 1,680W (336V multiplied by 5). Conversely, 400 amps at the same voltage would result in 134,400W (or 134.4 kilowatts). This illustrates the relationship between charge rates and power.

While the Equinox’s parallel cell configuration enhances its current absorption capacity, its low voltage inherently limits the pack’s power intake. This elucidates why high-voltage architectures can facilitate faster charging; increasing voltage yields a proportionally larger power increase if current remains constant—ultimately delivering more kilowatts.

Chevy Equinox EV 2024 Battery Technology

This explains why vehicles equipped with 800V-nominal packs can typically charge at speeds closer to 350kW. Many Hyundai and Kia models, the Lucid Air, and the Tesla Cybertruck are designed to operate at around 800V. The GMC Hummer EV, despite running its drive units at around 350V, can charge at approximately 800V by configuring its massive pack in a series, known as a “split pack setup.”

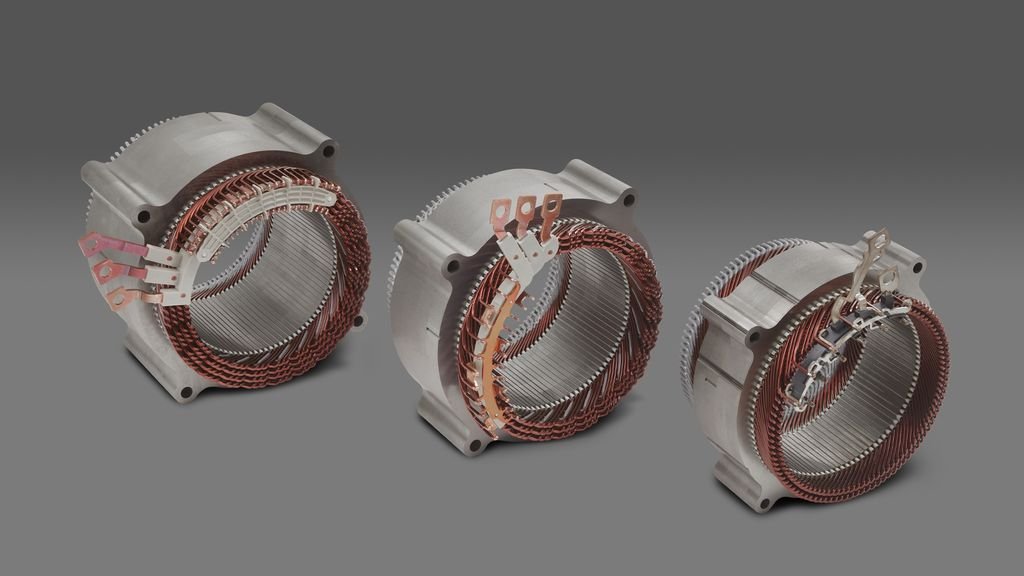

Lower voltage theoretically implies lower top-end performance, although this is a bit more intricate. Permanent magnet motor windings can be engineered to rotate at a specific speed for a given voltage, known as the motor’s kV rating. The kV represents motor RPM per volt of input. For instance, a 100kV motor will spin at 100 rpm with a single volt, 500 RPM with 5V, and so on. Electric drive units utilize a reduction gear to achieve wheel speeds, allowing for tailoring of the entire system—motor, reduction, and voltage—to achieve the desired compromise.

If you anticipate the vehicle primarily operating at high speeds, opting for a lower gear ratio might be preferable to ensure ample power at higher RPMs before the motor reaches its limit. However, this choice typically sacrifices torque, which necessitates compensatory measures involving amperage—a complex undertaking.

In the case of the Equinox EV, it’s evident that a compromise was made for a narrower range of operating speeds. Its front drive unit features an 11.59:1 ratio, slightly lower than the RWD Lyriq/Blazer’s 11.63:1 ratio (which is nearly identical). Assuming similar motor KV ratings—a reasonable assumption—this setup likely impacts top-end performance.

Practical experience with the FWD Equinox EV confirms this hypothesis; at speeds exceeding 75 mph, noticeable power depletion becomes apparent, stemming from a combination of these factors.

Conversely, examining the AWD Cadillac Lyriq reveals a different scenario. With front and rear drive units boasting ratios of 9.87:1 and 10.49:1, respectively, and a higher pack voltage plus dual drive units, the Lyriq enjoys increased current handling capacity. This translates to enhanced torque, elevated potential speed, and greater overall power.

This situation presents an intriguing dilemma for GM. It’s highly probable that GM will manufacture vehicles featuring lithium-ion NMC packs smaller than the Equinox’s hefty 85 kWh capacity. However, reducing the number of modules results in a significant decrease in voltage, posing a challenge. For instance, a 53 kWh pack utilizing six standard Ultium modules would yield a nominal voltage of just ~172.8V—suitable only for city cars. In fact, many small Chinese EVs operate within or even below this voltage range (consider the standard Nissan Leaf with a 40 kWh battery).

The only viable solution to this predicament is either the creation of a new module or the rewiring of existing ones. At first glance, it may appear that GM has painted itself into a corner in this regard.

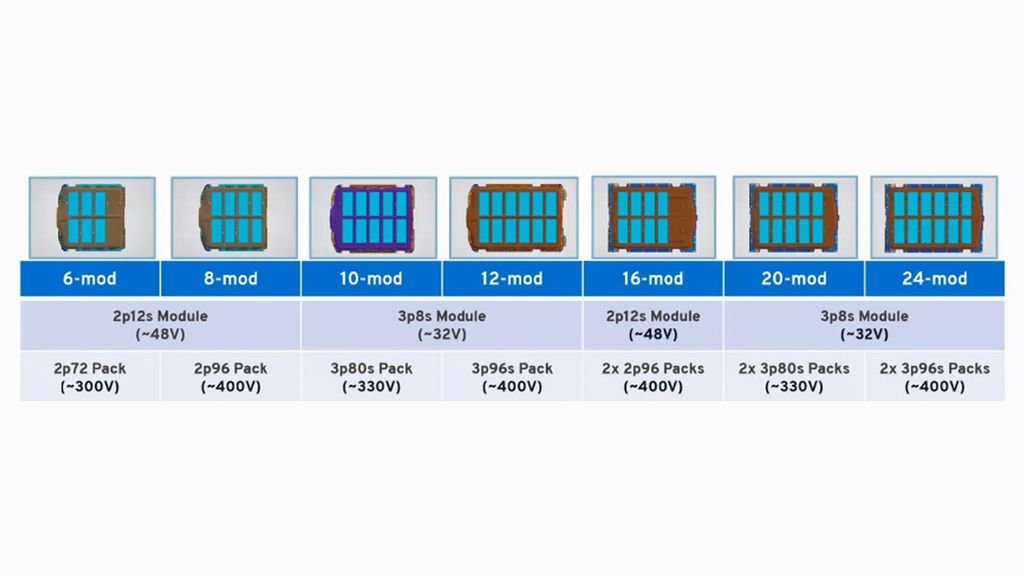

However, there’s potential for resolution through the layout of the basic Ultium module. Configured as 8S 3P for a total of 24 cells, this arrangement presents a conveniently divisible number. By rewiring to a 12S 2P configuration, a higher voltage per module can be achieved. While I’ve come across a chart outlining how GM might approach this solution, its official status is uncertain.

With a hypothetical 12S module, boasting approximately 43.2 volts nominal, a 53 kWh pack configured in this new 72S arrangement would not yield 172.8V, but 259.2V instead—placing it within the range of existing architectures.

Although I shared the previously mentioned chart with a GM representative, I was informed that the information was considered “outdated.” Car companies typically refrain from speculating on future products they haven’t formally announced. Consequently, I was advised that, at least for the time being, “there aren’t any smaller or larger modules.”

Gaining further insight on this matter might prove challenging because confirming the existence of a higher-voltage Ultium module effectively announces the development of smaller EVs—a detail beyond what’s currently known beyond the updated Bolt EUV.

Thus, the Equinox EV sheds light on GM’s electric strategy and its approach to various sizes and classes of vehicles. The decision to prioritize larger EVs for commercialization, along with the modules powering them, is evident. The Equinox stands as the smallest EV utilizing these lower-voltage modules, marking it as the company’s initial foray into small-ish Ultium EVs. Venturing even smaller would necessitate altering the module through rewiring.

For the forthcoming Ultium Bolt EUV, the shift to lithium-iron-phosphate (LFP) chemistry promises significant cost savings. However, the precise method by which the automaker intends to execute this transition remains undisclosed. It’s probable that a new battery cell and module will be necessary, but GM has declined to provide clarification on these specifics at present.

Scaling up production of both components right from the start presents a considerable challenge. With the Bolt EUV’s reveal date scheduled for next year, it’s evident that the company is working diligently to ensure all necessary pieces are in place for a successful launch.

Pingback: New Tesla Model S: What We Know So Far and Future Expectations - Electric Vehicle Buzz